As solar panels for homes and businesses become increasingly popular, more and more people learn about the solar installation process. But even though it’s relatively simple to find information about solar panel reviews, leading manufacturers, and even installers in your area, it can be challenging to locate details about certain highly specific (but necessary) topics – such as how to mount solar panels.

There are various methods for mounting solar panels, which we will walk you through in this handy guide. You’ll learn:

- What is solar panel mounting and racking?

- What are the components of a solar panel mounting system?

- How do you choose the best solar mounts for roof and ground installation?

- How much do solar panel mounts cost?

- Where do you buy solar panel mounts?

With this resource in hand, you’ll be well-equipped to choose the best solar panel mounts for your project.

What is Solar Panel Mounting and Racking?

Solar panel mounts and racks are specialized equipment systems used to install solar panel arrays in a secure, stable position. Solar panel arrays can be mounted in many ways: on building roofs, on poles in the ground, and even with tracking. A mounting system can also help optimize your solar panels’ location and position, maximizing sun exposure and overall performance and efficiency.

Ultimately, the objective is a solidly mounted solar panel array that will last for many years and withstand extreme weather. Several manufacturers make stationary solar panel mounting structures designed to work with almost any solar panel model. This hardware is intended for multiple applications and different mounting techniques, and considerations like wind and snow loads have been included in their design. Using fixed, stationary mounting hardware is the simplest and often the most cost-effective way to mount solar panels. Customized or sun-tracking array mounting structures can be expensive but could be ideal if you are dealing with a unique scenario.

No matter what mounting option you choose, it is crucial that all racking and mounting products meet the guidelines for durability and structural integrity. Settling for a flawed system can put you at risk of experiencing damage to your solar system during high winds or weather events – and the last thing you want is to sacrifice your investment – and potentially your source of electricity – just to save a few bucks on the mount.

Solar Panel Mounting Components

Three main components make up a solar mounting system:

- Roof attachments

- Mounting rails

- Module clamps

Each of these serves an essential role in supporting and stabilizing your panels.

Roof Attachments

The roof attachments are specialized fasteners drilled into the roof that allow for the secure attachment of the mounting rails. Your roof type determines your roof attachment options. For example, composite shingle roof attachments must include flashing (plastic or metal) to prevent leaks, while standing metal seam roof attachments utilize a clamp design.

Mounting Rails

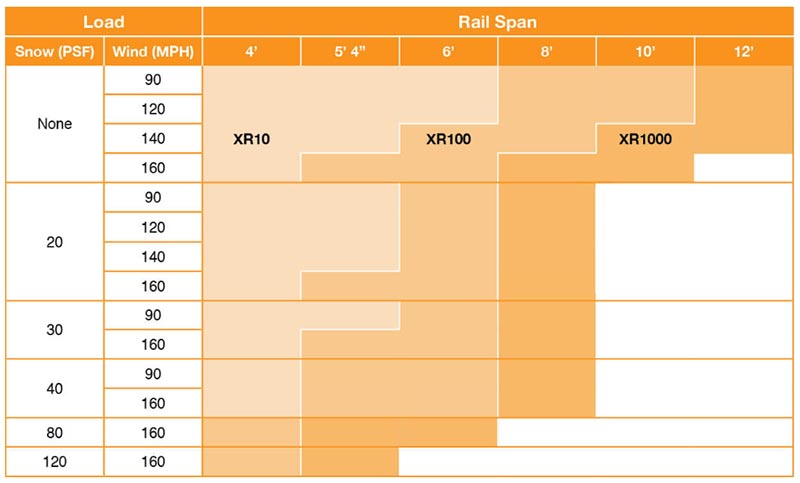

The mounting rails connect to the drilled-in roof attachments. These rails are what hold and support your solar panels. Solar panel mounting rails come in different thicknesses and lengths. Thicker rails are stronger and can support more weight and distance between roof attachments (known as “spans”). Thin rails like the IronRidge XR10 should not be used in climates where snow can accumulate on your solar panel array due to the added weight, whereas the IronRidge XR1000 can handle heavy snow loads.

There are options for racking with no rails (most notably mounting your solar panels on poles), but rails are the most common choice simply because they are exceptionally versatile and easy to work with. You can set up solar panels on many different roof angles with mounting rails.

Module Clamps

The module clamps fasten the solar panels (solar modules) to the mounting rails. Your module clamp options are determined by your mounting rails, not by your solar panels. Most module clamps available today are adjustable to be compatible with all standard solar panels.

A Note on Electrical Grounding

The National Electric Code (NEC) requires that all solar power system equipment be electrically bonded and grounded to the earth. Doing so keeps both the system and people in its vicinity safe should lightning or any other electrical current pass through it unexpectedly. Most solar panel racking and mounting systems have a solution for this by virtue of their required components or materials used. Still, it bears repeating: make sure your system is electrically bonded and grounded.

Where to Buy Solar Panel Mounts

You can find solar panel mounting systems for sale through direct distributors, like altE. We partner with manufacturers to give our customers access to industry-leading products, so you can eliminate the extra costs and hassle of buying through a solar installation company.

Expect to buy the individual components for mounting solar panels because there usually aren’t fully-constructed mounting systems available. This is because it would be challenging for manufacturers to create system designs that suit all possible roof sizes, slopes, and styles, not to mention ones sized for the specific number of solar panels in your system’s array(s). That said, roof mounting kits from Tamarack Solar are available for smaller arrays of 4 or 8 panels. These kits include all mounting and racking components needed except for flashing, which you can easily purchase separately.

How Much Does it Cost to Mount Solar Panels?

The price of a solar mounting system varies based on factors such as:

- The type of racking

- How much equipment you need

- Installation method (labor costs for professional vs. DIY)

A good rule of thumb is to plan to spend about 10% of the total cost of the solar energy system on mounting. For example, if your new solar energy system costs about $10,000, your mounting system would equate to about $1,000 of that total.

Selecting the Best Solar Mounts for Your Project

When shopping around for solar mounts for sale online, it’s easy to be overwhelmed by all the available options. But with an organized approach, you can make an informed choice that serves your needs.

Your budget, location, and other factors can significantly impact which mounting material is suitable for you. Let’s consider the characteristics of various mounting materials:

- Aluminum – lightweight, strong, and resistant to corrosion. Aluminum angle is easy to work with, you can drill holes into it with commonly available tools, and the material is compatible with most solar panel frames. Aluminum is not easy to weld.

- Angle Iron – easy to work with but corrodes rapidly. Galvanizing will slow corrosion, but mounting brackets and bolts will still rust, particularly in a wet environment. The material is readily available, and brackets can be welded easily.

- Stainless Steel – Expensive and difficult to work with but will last for decades. This may be a good investment in salt spray environments.

- Wood – Inexpensive, available, and easy to work with but may not withstand the weather for many years – even if treated with preservatives. Attaching modules to a wooden frame requires battens or clips to hold them.

Roof-Mounted Solar Panels vs. Ground-Mounted Solar Panels

There’s no question that roof-mounted solar panels are the most common in most areas. Because setting up solar panels on a roof often allows maximum sunlight exposure and doesn’t take up extra space on the property, many home and business owners prefer this method.

However, roof mounting solar panels is generally more complex than either ground mounting or pole mounting. Roof mounts are more challenging to install, mainly if the roof orientation and/or angle are not good for solar (for instance, north-facing or flat roofs).

Home and business owners that choose ground-mounted solar panels typically do so for one of four key reasons:

- They don’t have enough roof space for a roof-mounted system

- Their roof is north-facing or is shaded by trees or nearby structures, which is not ideal for solar panel output

- The ground allows for better optimization of the system

- They are using bi-facial solar panels

Roof mounting should also be avoided when the roof is nearing the end of its expected life (typically 20 years for a composite shingle roof). Disconnecting and removing the solar panels, racking, and mounting to get the roof replaced adds a lot of cost and complexity to the job – as does reinstalling all the solar equipment after the roof has been replaced. Keep in mind that roof-mounted solar panels extend the roof’s life beneath them by protecting them from the elements – so you don’t need a new roof if you want to roof-mount your solar panels, but you shouldn’t have an old one either.

Ground-mounted solar systems can be secured directly into the ground or attached to ballasted mounts. Ballasted solar mounts are freestanding, held down by the weight of the panels (and sometimes additional weight as well) but not secured in the ground. Since there isn’t any drilling required for ballasted solar mounts, this type is popular for ground-mounted systems.

There isn’t necessarily a right or wrong answer in the debate of roof vs. ground solar installation – it all comes down to the approach that works best for your project needs and goals.

Tips for Professional and DIY Solar Mount Installation

Depending on your skill and comfort level with home improvement projects and the specifics of your project, you might be weighing your options between professional or DIY solar installation. Whether you opt to hire a professional or install your mounting system yourself, here are a few tips to keep in mind:

- The foundation for the array should be designed to meet the wind and snow load requirements of the region. Wind load depends on the size of the array and the tilt angle. Ask a local contractor how to anchor your array to withstand the wind and snow expected in your area.

- Regardless of whether you buy or build the mounting structure, make sure it is anchored, and the modules are restrained.

- If roof mounting, allow a clear airflow path up the roof under the array. The array will operate cooler and produce more energy if it stands at least 3 inches off the roof.

- Penetrating the roof seal is inevitable – use flashing properly to avoid leaks.

- It is essential to secure your roof attachments firmly. Attaching them to the rafters will provide the best foundation, but this may be difficult because module size and rafter spacing are usually not perfectly compatible. If there is access to the underside of the roof, insert 2 x 6-inch blocks between the rafters and the attachment made to the blocks.

- Attaching the array to the roof’s plywood sheathing may result in roof damage, particularly if high winds are likely.

- IronRidge offers handy Design Assistant tools to guide you through the list of components you’ll need based on your location, wind/snow loads, type of solar panel, etc.

- Some pole mounts from companies like MT Solar allow you to assemble at waist level, wire the solar panels at eye level, then chain hoist your array up into position and adjust your tilt angle from the ground. No more heavy equipment, cranes, scaffolding, or large ladders are needed!

Shop Solar Mounting Parts for Sale Online Now

Are you interested in saving money and completing a solar project that meets your expectations? When you shop with altE, you can get all of the equipment you need to tackle a DIY solar installation – or you can buy the components and then hire a professional installer. Whichever option you choose, the cost is typically far less than what you would pay to hire a solar company to complete the process.

altE carries solar mounts and other equipment from the industry’s best, most innovative brands, selecting and stocking only the highest-quality items. Our customers know that they are investing in products and equipment that will last, making the most of their solar solution in the short and long term.

If you still have questions about which solar mounting system to buy, the altE team is happy to help. Contact us for more information or start shopping now!