We are no longer offering this product.

The below information is presented for informational purposes only. You may also find similar items in the category.- FEATURED PRODUCTS

- Solar Panels

- Solar Power Systems

- Productos Solares en Puerto Rico

- Charge Controllers

- Inverters

- Deep Cycle Batteries

- Solar Panel Mounts

- MORE PRODUCTS

- Cables & Wiring

- Enclosures, Electrical & Safety

- Inverter Power Panels & PreWired Systems

- Meters, Communications & Site Analysis

- Portable Power Systems

- Solar Water Pumps

- Voltage Converters

- Wind Turbines

- Books & Education

- * Clearance Sale *

- Hot Deals

- Open Box & Refurb Deals

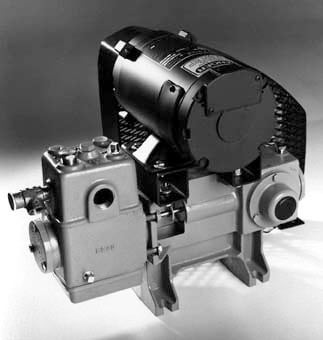

Dankoff Solarforce 3010-24B DC Surface Pump

| Item code | Brand name | Model number |

| DAKSF-3010-24B | Dankoff Solar Pumps | SOLARFORCE 3010-24B |

The SF-3010-24B now features the new Booster motor from Dankoff with increased double brush life expectancy. The surge tank is included with the pump.

![Dankoff Solar]() Dankoff

Solar

Dankoff

Solar

Solar Force

Piston Pump for Shallow Wells

Use Solar-Electric Power for water lift or pressurizing from shallow water sources. Provides as much as 5600 Gallons per day (21,000 ltrs.) pushing as high as 230 Feet (70m) or 100 PSI (7 kg/sq. cm)

Solar Force Piston Pump draws water from a shallow well, spring, pond, river or tank. It can push water uphill and over long distances for home, village, irrigation or livestock uses. It can use power directly from a photovoltaic array, or from storage batteries, to fill a storage tank or to pressurize water.

Ultra-Efficient: Uses less power than ANY other pump in its range

Economical: Reduces power system cost by 25-75% compared to centrifugal or AC pumps

Solar-Direct Application: Starts pumping in low light conditions

Pressurizing Application: DC version is most efficient. AC version uses a low-surge PM motor that greatly reduces starting surge, inverter size, and wire size requirements (when compared to conventional AC pumps).

Rugged and Reliable: Proven design with a 20-year life expectancy. Simple to maintain with common tools (2-6 yr. maintenance interval)

Mechanical Drive allows engine or hand-lever backup

Illustrated Instruction Manual makes it easy for anyone to install and service, with no previous experience.

Owners say:

"We have one pump that serves a community of 30 people and visitors. It more than adequately meets our needs." Brother Philip, Christ in the Desert Monastary, Abiquiu, New Mexico

"I want to tell you how happy I am with our Solar Force Piston Pump. What a workhorse! Gallon for gallon, the price of the pump is well worth it in quality and performance." R.S., Molokai, Hawaii

"Nothing will pump more water per watt than the Solar Force -- Nothing! And, it's built like a tank. I've seen similar pumps 50 years old, still working." Larry Elliot, Solar Tech, Bend, Oregon

Performance Chart

Reading the Chart

- Total Lift = Vertical Distance from surface of the water source to the pipe outlet or top of storage tank

- Model Designation: V=Voltage, B=Battery Model, PV=PV Array-Direct Model

Voltages Available

- 12, 24, 48, 90 VDC

Note: PV-Direct full working voltage is typically 20% higher than nominal (example: 29 Volts for a 24V system) - 115V or 230V AC, 50-60Hz

Suction Capacity

25 vertical feet (7.6m) at sea level. Subtract 1 foot for every 1000 ft. elevation (1m for every 1000m). Suction capacity may be further limited by intake pipe friction or gasses in water. Intake piping should be minimum 1 inch (3010, 3020 models) or minimum 1 1/4 inch (3040). For best reliability, place the pump as close to the water source as possible.

Construction

- Cast iron body

- Brass cylinder and valve seats

- Leather cup piston seals

- Neoprene valve seals

- Oil-bath crankcase with PTFE oil additive

- Gear (timing) belt drive on PV models

- Standard V-belt on B models

- Pressure relief valve

- Permanent Magnet DC Motor

System Requirements

- Solar-Direct Systems: Chart indicates power (watts) required at the pump. The rated power of the PV array must exceed this number by 20% or more. A pump controller (linear current booster) is required for the pump to start and run in varying light conditions. A solar tracker may be used to increase daily yield (40-55% in summer).

- Pressurizing Systems: Battery power system, pressure switch, and pressure tank of minimum 60 gallon (230 l) size (captive-air tank, available locally)

- Foot valve (if pump is placed higher than water source)

Accessories

- Foot Valve FV-3000 (1-1/4 inch) required if pump is placed higher than water source

- Pressure Switch: Heavy Duty DC rated, for pressurizing systems

- Surge Tank: Absorbs pulsation if long piping is required between pump outlet and tank (Included with PV models)

- Seal & Gasket Set : Spare gaskets, rod and valve seals, two sets of piston seals, and a belt

- Long-Term Parts Kit: The above, plus a second belt, motor brushes, cylinder sleeve, 2 oil changes

- Easy Installation Kit includes: Pressure Switch, Pressure Gauge, Check , Drain & Shut-Off Valves, & Tank Tee (manifold)

Fittings

- Intake: 1 1/4 inch female pipe thread

- Outlet: 1 inch female pipe thread

Dimensions

- 22 X 13 X 16 in. High (56 X 33 X 41 cm)

- With Surge Tank, 26 in. High (60 cm)

- Weight, max. 80 lbs (36 kg) (Shipped in 2 or 3 parcels)

Warranty

- 2 years against defects in materials and workmanship

| Surface Pumps Comparison | ||||||||||

| Surface pumps for lifting and/or pressurizing water / 1 PSI = 2.307 ft. of | ||||||||||

| Surface Pumps | Min Lift (ft) | Max Lift (ft) | Min Lift (PSI) | Max Lift (PSI) | Min GPM | Max GPM | Pump Type | Dirt Tolerant | Filtration Required | Dry-run Tolerant |

Solar Slowpumps 15xxx* |

0 | 440 | 0 | 191 | 0.4 | 4 | rotary vane | N | 10 mic | N |

Solar Slowpumps 14xx and 26xx |

160 | 440 | 69 | 191 | 1 | 4 | rotary vane | N | 10 mic | N |

Flowlight Booster Pumps 16xxx** |

69 | 150 | 30 | 65 | 3 | 4 | rotary vane | N | 10 mic | N |

SunCentric Pumps 7xxx |

0 | 90 | 0 | 39 | 5 | 70 | centrifugal | high | N | Y |

SolarForce PistonPumps 30xx |

0 | 220 | 0 | 95 | 4 | 9 | piston | medium | N | Y |

| Solaram Pumps 8xxx |

0 | 960 | 0 | 416 | 3 | 9 | diaphragm | medium | N | Y |

*formerly 13xx and 25xx

**formerly 29xx

Dankoff

Solar

Dankoff

Solar