For those that are new to solar power and photovoltaics (PV), unlocking the mysteries behind the jargon and acronyms is one of the most difficult early tasks. Solar panels have many different voltage figures associated with them. There is a good amount to learn when it comes to solar panel output.

Types of solar panel voltage:

- Voltage at Open Circuit (VOC)

- Voltage at Maximum Power (VMP or VPM)

- Nominal Voltage

- Temperature Corrected VOC

- Temperature Coefficient of Voltage

- Measuring Voltage and Solar Panel Testing

Voltage at Open Circuit (VOC)

What is the open circuit voltage of a solar panel? Voltage at open circuit is the voltage that is read with a voltmeter or multimeter when the module is not connected to any load. You would expect to see this number listed on a PV module’s specification sheet and sticker. This voltage is used when testing modules fresh out of the box and used later when doing temperature-corrected VOC calculations in system design. You can reference the chart below to find typical VOC values for different types of crystalline PV modules.

| Nominal Voltage | VOC – typical | VMP – typical | # of cells in series |

|---|---|---|---|

| 12 | 21 | 17 | 36 |

| 18 | 30 | 24 | 48 |

| 18 | 33 | 26 | 54 |

| 20 | 36 | 29 | 60 |

| 24 | 42 | 35 | 72 |

Voltage at Maximum Power (VMP or VPM)

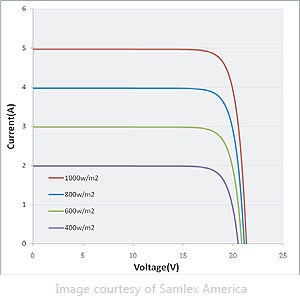

What is the Max Power Voltage of a solar panel? Voltage at maximum power is the voltage that occurs when the module is connected to a load and is operating at its peak performance output under standard test conditions (STC). You would expect to see this number listed on a modules specification sheet and sticker. VMP is at the place of the bend on an I-V curve; where the greatest power output of the module is.  It is important to note that this voltage is not easily measured, and is also not related to system performance per se. It is not uncommon for a load or a battery bank to draw down the VMP of a module or array to a few volts lower than VMP while the system is in operation. The rated wattage of a PV module can be confirmed in calculations by multiplying the VMP of the module by the current at max power (IMP). The result should give you P@MPP or power at the maximum power point, the same as the module’s nameplate wattage. The VMP of a module generally works out to be 0.5 volts per cell connected in series within the module. You can reference the chart to find typical VMP values for different types of crystalline modules.

It is important to note that this voltage is not easily measured, and is also not related to system performance per se. It is not uncommon for a load or a battery bank to draw down the VMP of a module or array to a few volts lower than VMP while the system is in operation. The rated wattage of a PV module can be confirmed in calculations by multiplying the VMP of the module by the current at max power (IMP). The result should give you P@MPP or power at the maximum power point, the same as the module’s nameplate wattage. The VMP of a module generally works out to be 0.5 volts per cell connected in series within the module. You can reference the chart to find typical VMP values for different types of crystalline modules.

Nominal Voltage

What is the voltage of a solar panel? Nominal voltage is the voltage that is used as a classification method, as a carry-over from the days when battery systems were the only things going. You would NOT expect to see this number listed on a PV module’s specification sheet and sticker. This nomenclature worked really well because most systems had 12V or 24V battery banks. When you had a 12V battery to charge you would use a 12V module, end of story. The same held true with 24V systems. Because charging was the only game in town, the needs of the batteries dictated how many cells inside the PV should be wired in series and or parallel, so that under most weather conditions the solar modules would work to charge the battery(s). If you reference the chart, you can see that 12V modules generally had 36 cells wired in series, which over the years was found to be the optimum number for reliable charging of 12V batteries. It stands to reason that a 24V system would see the numbers double, and it holds true in the chart. Everything worked really well in this off grid solar system as the and evolved along the same nomenclature so that when you had a 12V battery and you wanted solar power, you knew you had to get a “12V” module and a “12V” controller. Even though the voltage from the solar module could be at 17VDC, and the charge controller would be charging at 14V, while the inverter was running happily at 13VDC input, the whole system was made up of 12V “nominal” components so that it would all work together. This worked well for a good while until maximum power point technology (MPPT) became available and started popping up. This meant that not all PV was necessarily charging batteries and that as MPPT technology evolved, even when PV was used in charging batteries, you were no longer required to use the same nominal voltage as your battery bank. String inverters changed the game for modules, as they were no longer forced in their design to be beholden to the voltage needs of deep cycle batteries. This shift allowed manufacturers to make modules based on physical size, wattage characteristics, and use other materials that produced module voltages completely unrelated to batteries. The first and most popular change occurred in what are now generally called 18V “nominal” modules. There are no 18V battery banks for RE systems. The modules acquired this name because their cell count and functional voltage ratings put them right in between the two existing categories of 12V and 24V “nominal” PV modules. Many modules followed with 48 to 60 cells, that produced voltages that were not a direct match for 12V or 24V nominal system components. To avoid bad system design and confusion, the 18V moniker was adopted by many in the industry but ultimately may have created more confusion among novices that did not understand the relationship between cells in series, VOC, VMP, and nominal voltage. With this understanding, things get a lot easier, and the chart should help to unlock some of the mystery.

Temperature-Corrected VOC

The temperature-corrected VOC value is required to ensure that when cold temperatures raise the VOC of an array, other connected equipment like MPPT controllers or grid tie inverters are not damaged. This calculation is done in one of two ways. The first way involves using the chart in NEC 690.7. The second way involves doing calculations with the Temperature Coefficient of Voltage and the coldest local temperature.

Temperature Coefficient of Voltage

What is a solar panel temperature coefficient? The temperature coefficient of a solar panel is the value represents the change in voltage based on temperature. Generally, it is used to calculate Cold Temp/Higher Voltage situations for array and component selection in cooler climates. This value may be presented as a percentage change from STC voltages per degree or as a voltage value change per degree temp change. This information was not easily found in the past, but is now more commonly seen on spec pages and sometimes module stickers.

Measuring Voltage and Solar Panel Testing

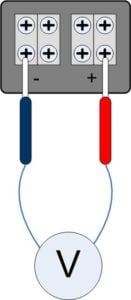

How do I measure voltage on a solar panel? Voltages can be read on a solar panel with the use of a voltmeter or multimeter. What you’ll see below is an example of a voltmeter measuring VOC with a junction box. This would be the view from the back of the PV module. Using a multimeter is the best way to measure solar panel output.

When researching solar panel output, it can be overwhelming to understand the different voltage figures and acronyms used. For those new to solar power and photovoltaics (PV), decoding the terminology can be a challenge. In this blog post, we will break down the basics of solar panel output, including voltage, acronyms, and jargon, to help you get up to speed.

What are solar amps and watts?

Solar amps and watts are two measurements of the amount of electrical energy that a solar panel produces. Solar amps (A) measure the rate of electric current produced by a photovoltaic cell, while solar watts (W) measure the amount of power delivered to an electrical load. Both solar amps and watts are related to the efficiency rating of residential solar panels. The higher the efficiency rating, the higher the number of solar amps and watts produced.

There are many types of 60-cell solar panels on the market for home solar applications, each with varying efficiency ratings and amp/watt outputs. High efficiency panels are capable of producing more solar watts than low-efficiency panels, although they tend to cost more upfront. By choosing the right panel, homeowners can ensure that their solar array is producing enough power to meet their electricity needs.

Why do solar panels have so many voltages associated with them?

Solar panels have a variety of voltage figures associated with them due to the different types of solar panels, their placement in a solar panel system, and their power production. The most common type of rooftop solar panel uses a direct current (DC) and produces a low voltage. This low voltage is typically between 20 and 40 volts, depending on the specific type of panel. To increase the voltage output, multiple solar panels can be wired together in a series or parallel connection, or both, depending on the specific solar energy system.

When solar panels are connected in a series, the voltages are added together. This means that connecting two 20-volt solar panels in series would yield a total voltage output of 40 volts. Connecting three panels in series would result in a 60-volt output, and so on. This method is often used when the total voltage needs to be higher than what a single panel can provide.

In contrast, when solar panels are connected in parallel, the wattage is added together. This means that connecting two 10-watt solar panels in parallel would yield a total wattage output of 20 watts. Connecting three panels in parallel would result in a 30-watt output, and so on. This method is often used when the total wattage needs to be higher than what a single panel can provide.

The voltage output of a solar panel also depends on its power production, which is measured by the manufacturer at Standard Test Conditions (STC).

What does STC mean?

STC is defined as an irradiance of 1,000 W/m2 and cell temperature of 25 degrees Celsius. Because real-world conditions are rarely equal to STC, the actual power output of a solar panel may differ from its rated output. This is why it’s important to understand the various voltages associated with your particular solar energy system to ensure it meets your needs. To determine solar panels rated output, you need to know two figures: the solar panel wattage (measured in watts) and solar panel efficiency (measured in percent). Solar installation involves connecting solar panels to a photovoltaic system that can use or store the generated electricity. The efficiency rating of solar panels varies depending on factors such as environment, angle, and geographic location, but typically ranges between 15–20%. Knowing what wattage solar panels generate helps determine their overall performance in terms of power production for any given solar installation project. Understanding the various voltages associated with solar energy systems can be challenging for those new to the technology but once you’ve grasped this knowledge, you’ll have the knowledge you need to make informed decisions about your own solar energy installation.

How many size should my solar panel be?

When choosing a solar panel size, you must consider your energy needs and the hours of sunlight available in your area. The size of the solar panel will determine how much electricity it can produce, measured in kilowatt hours (kWh). Your energy needs will determine the type of solar panel that you need.

If you’re looking to produce a specific amount of electricity, the total number of solar panels that you need will depend on their wattage rating. Generally, the higher the wattage rating, the more electricity it will generate. You can calculate how many solar panels you need to meet your energy requirements by dividing your kWh requirement by the wattage of each panel.

For example, if you have an energy requirement of 10 kWh per day and you are using solar panels with a rating of 250 watts, then you would need 40 solar panels.

When choosing the size of your solar panel, make sure to consider the hours of sunlight available in your area as well. The more sunlight available, the fewer solar panels you’ll need to meet your energy requirements.

In summary, the size of the solar panel that you need depends on your energy needs and the hours of sunlight available in your area. You can calculate how many panels you need to meet your energy requirements by dividing your kWh requirement by the wattage of each panel.